Have you ever stayed up late pondering the best thickness for luxury vinyl plank flooring? If so, you could be feeling stressed about a renovation, or maybe you’ve watched one too many home improvement shows. The thickness of your floors influences not just their durability and quality but also how comfortable they are and how much maintenance they’ll need.

Our luxury vinyl plank floor thickness guide will cover everything you need to know to figure out the right thickness for your floors, the four main layers of vinyl flooring, and why the wear layer thickness should be among the most important factors you should focus on.

- Summary: What is the Best Vinyl Floor Thickness? How Thick Should Vinyl Flooring Be?

- Wear Layer (mils) & Overall Thickness (mm): How Is Vinyl Plank Thickness Measured and Calculated?

- Understanding Vinyl Flooring Layers, Thickness, Wear Layer, & Quality Specs

- What Is The Best Thickness For Vinyl Plank Flooring?

- Thickness of Different Types of Vinyl Flooring

- Cost and Useful Life of Vinyl Plank Based On Thickness

- Factors to Consider When Choosing the Right Thickness for Your Luxury Vinyl Plank Flooring

- 5 Things to Know Before Buying LVP

- Residential or Commercial Rating

- FAQ

- Final Thoughts

Summary: What is the Best Vinyl Floor Thickness? How Thick Should Vinyl Flooring Be?

The thickness of vinyl flooring is important for its durability, comfort, and ability to reduce noise. In general, vinyl plank thicknesses range from 2mm to over 8mm.

Choosing the right vinyl flooring thickness depends on the amount of foot traffic and where you plan to install it:

- 2-4mm: Perfect for low-traffic spaces like bedrooms, laundry rooms, or storage rooms. It’s affordable and easy to install, clean, and maintain.

- 4-6mm: Great for high-traffic areas such as kitchens, entryways, and living rooms. It provides extra durability, comfort, resistance to scratches, and noise reduction. It can also help cover small imperfections in your subfloor.

- 6-8mm: Ideal for commercial spaces with heavy foot traffic like offices, restaurants, and retail stores. This thickness offers more durability and better soundproofing.

Thicker options tend to cost more but offer longer-lasting performance, better scratch resistance, and can include more intricate textures.

Wear Layer (mils) & Overall Thickness (mm): How Is Vinyl Plank Thickness Measured and Calculated?

The wear layer of Luxury Vinyl Plank (LVP) flooring is measured in mils, while the total thickness is measured in millimeters (mm).

Plank Thickness Overview: LVP planks usually range from 4-8 mm thick, with wear layers between 6 and 20 mils. Budget-friendly vinyl typically ranges from 2-4 mm, while high-end vinyl can often be found in 5-8 mm thicknesses.

The wear layer is measured in mils (one-thousandth of an inch). A mil is different from a millimeter – about 40 mils equal 1.0 mm (exactly 39.4 mils to 1 mm). The total thickness, however, refers to the full height of the flooring, including all layers (wear layer, decorative layer, and backing).

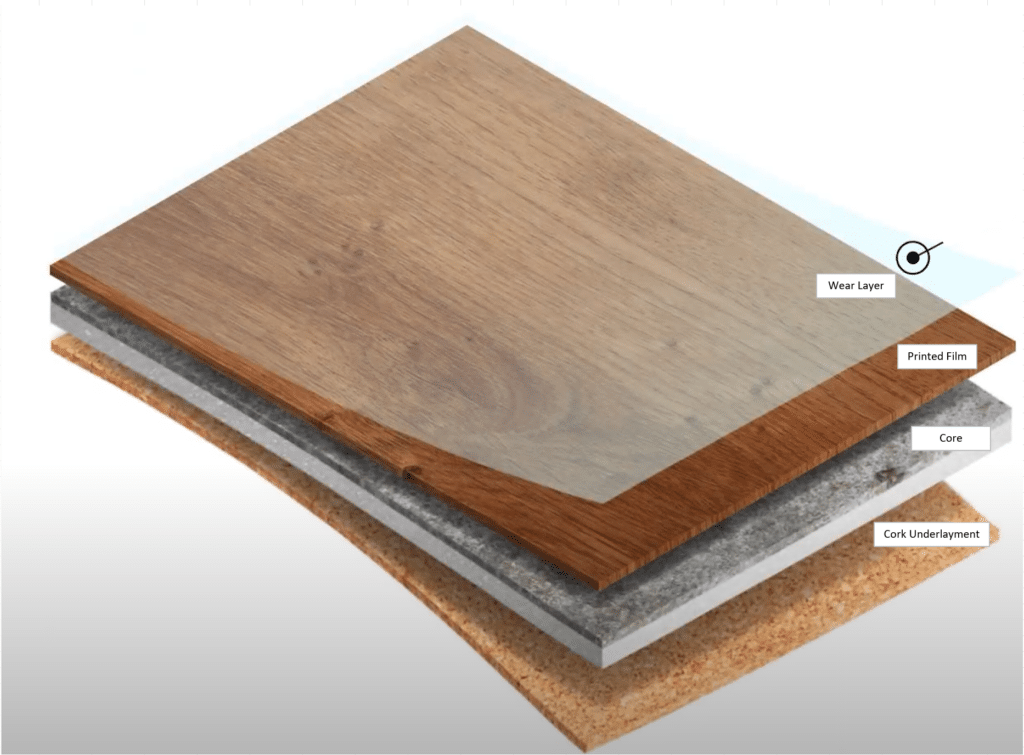

To understand the thickness of a vinyl plank, you need to consider the wear layer, core, and backing. Having a basic idea of how manufacturers put together vinyl planks will help you evaluate your options.

The total thickness is measured in millimeters (1 mm = 3/64 of an inch). There is a wide variety here, with lower-quality planks measuring around 4 mm and higher-quality planks reaching 8 mm or more. For example, a 6 mm thick floor with a 1.5 mm pad actually has a total thickness of 4.5 mm.

Are you planning to transition from your vinyl planks to another flooring type? If so, keep that in mind when determining the plank thickness. Poorly planned transitions between rooms can result in uneven and unattractive floors.

Also Read: How to Clean Vinyl Plank Flooring Safely | Tips from the Pros

Understanding Vinyl Flooring Layers, Thickness, Wear Layer, & Quality Specs

1. Wear Layer

In general, the thicker the wear layer, the longer-lasting the vinyl plank will be.

The wear layer is located on top, positioned between the printed design film and the coating that covers the plank. This layer is the most important factor in determining how well your floor will perform over time.

A thicker wear layer offers better protection against scratches and dents. High-quality flooring often has the thickest wear layers but tends to cost more. A simple tip is to buy the thickest wear layer you can afford.

NOTE: The wear layer usually ranges from 0.1 mm to 0.7 mm in thickness.

If the wear layer wears out, the printed design underneath will be damaged and start to fade. The thicker the wear layer, the longer it takes for the top layer to wear down and expose the vinyl design.

However, no matter how thick the wear layer is, the floor will still get scratched eventually if not properly cared for.

Expert Tip: A thicker wear layer improves durability, but in low-traffic areas, you might prefer overall thickness for added comfort. In homes, wear layer thickness is usually less of a concern, though it matters more in commercial spaces.

Overall LVP Thickness vs. Wear Layer Thickness

In short, the wear layer thickness matters more than the total thickness of a luxury vinyl plank.

Let’s look at an easy example:

Plank #1

- Overall Thickness: 8 mm

- Wear Layer: 10 mils

Plank #2

- Overall Thickness: 6 mm

- Wear Layer: 20 mils

WINNER – We’d choose this plank because the wear layer is much thicker, offering better protection for a longer time. The overall thickness of the plank is less important.

12 mil vs. 20 mil Vinyl Plank Flooring

In general:

- Best: >20 mils

- Good: 12 mils

- Below Average: 6 mils (be wary of floors below 6 mils in wear layer)

A good wear layer for vinyl plank flooring should be at least 12 mil. If you have an active family or pets, it’s worth considering a 20 mil or thicker wear layer. (See our guide for the best flooring for pets.) For commercial use, vinyl planks with a 28 mil wear layer are recommended.

Even with a thicker wear layer, your floors may not last as long as expected. Other factors like plank construction, installation, and maintenance play a key role in their longevity.

2. Top Coating

Additives like aluminum oxide coatings can boost the strength and performance of vinyl planks.

The top layer on the wear surface is also crucial. Higher-quality vinyl floors include a wear layer with a protective top coat, often made with additives like ceramic to make the planks harder. We prefer vinyl planks that feature a wear layer with a top coating containing aluminum oxide.

Shaw floors typically have aluminum oxide, while COREtec floors use a UV-cured finish. Both options do an excellent job of creating a tough top coat that improves durability. Some vinyl planks also use a urethane coating with small ceramic beads mixed in to add extra strength and grip.These substances must bond with the flooring during manufacturing through a curing process. If the bonding isn’t done properly, the coating won’t work as intended. Be sure to check the warranty for details about manufacturer defects.

3. Printed Film

A printed film is applied over the core with paper print to achieve the desired style and color. This layer is more focused on appearance than thickness or durability.

4. Core

Beneath the protective wear layer, vinyl flooring has additional backing layers, including the core and underlayment. The core is the thickest part of the plank, providing stability and strength.

Types of Luxury Vinyl Plank & Tile Flooring Based on Their Core

Most luxury vinyl planks (LVP) feature either a WPC (Wood Plastic Composite) or SPC (Stone Plastic Composite) core.

- Stone Plastic Composite (SPC): 4-8mm Plank Thickness | 6-20 mils Wear Layer

- Wood Plastic Composite (WPC): 5-9mm Plank Thickness | 6-20 mils Wear Layer

WPC is softer, warmer, and quieter but may dent more easily. SPC, however, is harder and more durable due to its stone particle makeup, though it’s louder and less comfortable than WPC. WPC doesn’t contain real wood, it’s made from wood flour mixed with thermoplastic and calcium carbonates. This type of flooring is free of phthalates and is safer for your family.

If we had to choose, we would slightly prefer SPC, as it’s affordable (under $2 per square foot) and long-lasting.Check out our full comparison of SPC vs. WPC.

5. Underlayment and Balancing Layer

The underlayment and balancing layer serve multiple functions, including providing a softer feel, acting as a moisture barrier, and reducing sound. It also enhances stability. It typically adds about 1mm to the thickness of the vinyl plank or tile.

You won’t find a balancing layer on many lower-cost floors (under $2 per square foot), as manufacturers cut this feature to lower the price. If you live in a humid area or your floors get a lot of direct sunlight, lacking a balancing layer could cause the floor to warp or separate.

Expert Tip: We don’t recommend buying a floor without a balancing layer. If you need to match the height of nearby floors, thicker backing layers may be necessary.

What Is The Best Thickness For Vinyl Plank Flooring?

For areas with heavy foot traffic, it’s best to choose a wear layer of 20 mils. For spaces with light to moderate traffic, a 12-mil wear layer is sufficient.

Check our vinyl thickness chart for more guidance:

| Type | Wear Layer We Recommend |

|---|---|

| Peel & Stick Flooring | 6 mils |

| Loose Lay Vinyl Flooring | 12 mils to 20+ mils |

| Glue Down Vinyl | 12 mils to 20+ mils |

| Click and Lock Vinyl | 12 mils to 20+ mils |

Thickness of Different Types of Vinyl Flooring

Here’s a quick overview of three common vinyl flooring types and their thickness ranges:

| Luxury Vinyl Planks (LVPs) | Luxury Vinyl Tiles (LVTs) | Vinyl Sheet |

|---|---|---|

| – Commonly used in both homes and businesses. – Composed of three layers: PVC vinyl, a realistic design layer, and a protective coating. – Designed to resemble real wood with lifelike textures and finishes. – A budget-friendly option for a warm and inviting appearance. Thickness: Typically ranges from 2-8 mm, with thicker options (6-8 mm) providing better durability. | – Has similar layers to LVPs but is designed to look like stone or ceramic. – Comes in a wide range of customizable designs. – High water resistance and low-maintenance, ideal for kitchens and bathrooms. Thickness: Usually between 1-8 mm, with peel-and-stick versions being thinner (1-1.5 mm). | – Made in large rolls to create seamless designs. – Mimics natural materials like wood, stone, and marble. – The smooth surface improves water resistance. – Perfect for creating complex mosaic patterns. – Often used in schools and offices. Thickness: Around 6-8 mm, making it suitable for heavy-duty use. |

Cost and Useful Life of Vinyl Plank Based On Thickness

| 20 mil Vinyl Plank Flooring | 12 mil Vinyl Plank Flooring | 6 mil Vinyl Plank Flooring |

| $3 to $8 per SF | $2 to $5 per SF | $1 to $4 per SF |

| 20 year useful life | 7-10 year useful life | 4-5 year useful life |

Cost should not be the only thing you should consider, give equal weight to the durability of a higher-quality floor.

LVP Thickness – Our Picks for Top Brands

- 20 mil wear layer

- 8.0 mm overall

- $5 to $6 per SF

- 20 mil wear layer

- 6.0 mm overall

- $5 to $7 per SF

- 30 mil wear layer

- 3.0 mm overall

- $6 to $8 per SF

Factors to Consider When Choosing the Right Thickness for Your Luxury Vinyl Plank Flooring

Selecting the appropriate thickness for your vinyl flooring is essential for durability and to ensure it can handle the weight of heavy appliances and furniture. In addition to the wear layer and the vinyl plank’s core, here are other aspects to think about when deciding on vinyl flooring thickness:

#1. Subfloor

The type of subfloor (whether concrete, plywood, or existing flooring) affects the necessary thickness of vinyl. Thicker planks are better at masking imperfections on uneven subfloors, while thinner planks may highlight these flaws. For most homeowners, luxury vinyl planks and tiles are recommended for their water resistance, scratch resistance, and easy click-lock installation.

#2. Foot Traffic

The level of foot traffic in a space impacts the thickness you should choose:

- Low-Traffic Areas (e.g., bedrooms, home offices): Thinner planks work well.

- High-Traffic Areas (e.g., living rooms, commercial spaces): Opt for thicker planks (12 mm-20 mm) to handle wear and tear.

Thickness Considerations: The thicker does not always mean the better.

Thicker vinyl flooring has its perks, but the highest thickness isn’t always essential. Different spaces, such as kitchens, bathrooms, or offices, have specific requirements. Thicker planks, however, are more stable for supporting heavy furniture.

Summary: Cheat Sheet for Your Vinyl Flooring Wear Layers

- 6-mil: Light residential areas (e.g. bedrooms).

- 12-mil: Moderate residential use (e.g. living rooms).

- 20-mil: Young families or light commercial spaces (e.g. offices).

- >20-mil: Heavy commercial use (e.g. retail stores).

Choosing the Right LVP Thickness: Room-by-Room Recommendations

- Kitchens: Minimum 5 mm thickness with a 20+ mil wear layer to resist spills and scratches.

- Living Rooms/Bedrooms: 4-6 mm thickness and a 12-20 mil wear layer for moderate foot traffic and comfort.

- Bathrooms: At least 5 mm thickness with a 20+ mil wear layer for water resistance and durability.

- Dining Rooms: 5 mm thickness and 20+ mil wear layer to protect against chair marks.

- Basements: Choose planks with a thickness of 5+ mm and focus on waterproof options.

- Laundry Rooms: Thicker planks provide added water resistance.

- Playrooms/Family Rooms: 5 mm+ thickness and a 12-20 mil wear layer for longevity.

- Hallways/Entryways: At least 5 mm thickness and a 20+ mil wear layer to handle heavy traffic, dirt, and scratches.

- Guest Rooms/Home Offices: 4-6 mm thickness with a 12-20 mil wear layer for durability.

- Commercial Spaces: Use thicker planks (6-8 mm+) with 20+ mil wear layers to support heavy furniture and frequent foot traffic.

Bonus: Locking Mechanism as Another Important Factor to Consider to Ensure the Longevity of Your Vinyl Flooring

Thicker planks generally result in a stronger and more reliable locking system. Below are the three main installation methods:

- Click Lock: Features interlocking edges that connect the planks without needing nails or glue, making it ideal for DIY installations.

- Glue-Down: Involves securing planks to the subfloor with adhesives for enhanced stability. While it’s sturdier than floating installations, professional help is recommended.

- Loose-Lay Technology: Relies on suction and friction for easy setup, but its long-term durability isn’t well-documented.

5 Things to Know Before Buying LVP

- Order full-size plank samples. While it might cost a little, it’s worth it to visualize the look and test the product.

- Perform the butter knife test: Scratch the plank with normal force using a butter knife. If multiple scratches appear easily, avoid purchasing that product.

- Ensure the subfloor is level and in good condition.

- Invest in the highest wear layer you can afford for better longevity.

- Test the locking areas by attempting to snap them off by hand. If they break easily, skip that option.

Residential or Commercial Rating

Another key factor to think about is the rating: Is it designed for residential or commercial use? Both types have the same upkeep needs, but planks meant for businesses are built to endure heavier usage.

It’s useful to compare the warranty for commercial use with the one for residential use. A longer industrial warranty typically means a thicker wear layer.

Flooring makers often play it safe when dealing with commercial clients. By giving vinyl planks a lower life expectancy, they avoid expensive warranty claims.

On the other hand, residential flooring is meant to handle less wear over a longer time. If your home’s planks need to endure heavy loads, grease, or intense use, choosing the commercial-grade rating is a better way to judge how long your vinyl planks will last.

FAQ

The overall thickness of the vinyl isn’t as important as the wear layer. It’s best to have a wear layer of 12 mils or more.

How thick is 20 mil vinyl flooring?

20 mils is about 0.5 mm. Remember, mils and millimeters are different units of measurement.

Is thicker vinyl flooring better?

In most cases, yes, but the key factor is the components that make up the thickness. The wear layer plays the biggest role. For example, if you have an 8mm thick vinyl floor with 2mm of padding, the vinyl itself is only 6mm thick.

Can I increase wear layer of LVP?

No, you can’t add a wear layer to a floor that’s already installed. The wear layer is added during the manufacturing process.

What is a good thickness for vinyl sheet flooring?

Vinyl sheet flooring tends to be thinner than vinyl plank, so a thickness between 2mm and 5mm is generally enough for most situations.

Final Thoughts

If durability is your top priority, choose vinyl planks with the thickest wear layers. Your retailer should provide detailed information about these specifications.

When selecting vinyl planks, consider factors like warranty, core construction, wear layer thickness, and any attached underlayment. Planks with added padding offer more warmth and noise reduction, and some include built-in vapor barriers in the underlayment.

Don’t assume pricier flooring is always better. While this is often true, higher costs can sometimes reflect branding rather than quality. Always verify that the product meets health standards and carries proper safety certifications.

If you’ve had a great experience or a disappointing one with vinyl planks, share your comments to help others make informed choices.

Back to Top